Installation

Thin Slate Stone Veneer can be glued to surfaces using most standard laminate adhesives having a thick body or foaming quality. Prior to application of the glue clean, brush and de-grease the receiving surface or dust, oils or any other contaminants. In same installations, and depending upon the adhesive used, it may be necessary to prepare the back of the thin Slate Stone veneer with solvent or recommended primer by the adhesive manufacture. We recommend making a test area with any adhesive prior to final application.

Thin Slate Stone Veneer can be glued to surfaces using most standard laminate adhesives having a thick body or foaming quality. Prior to application of the glue clean, brush and de-grease the receiving surface or dust, oils or any other contaminants. In same installations, and depending upon the adhesive used, it may be necessary to prepare the back of the thin Slate Stone veneer with solvent or recommended primer by the adhesive manufacture. We recommend making a test area with any adhesive prior to final application.

Useful Information's

PRESSING

Stone-Veneer has a natural, rough split surface with a tolerance of up to 2 mm. Thickness equalizing additions protect the veneers from being damaged. Proven are 7 mm thick rubber plates with a shore grade of 50 and a temperature Resistance of at least + 80° C. It is important that the rubber matt has an insulating effect, so that the press time can be therefore extended. Pending on the adhesive type and press temperature of 80° C, press time approximately 6 minutes. Depending on the press configuration, the pressure has to be carefully set.

Stone-Veneer has a natural, rough split surface with a tolerance of up to 2 mm. Thickness equalizing additions protect the veneers from being damaged. Proven are 7 mm thick rubber plates with a shore grade of 50 and a temperature Resistance of at least + 80° C. It is important that the rubber matt has an insulating effect, so that the press time can be therefore extended. Pending on the adhesive type and press temperature of 80° C, press time approximately 6 minutes. Depending on the press configuration, the pressure has to be carefully set.

ADHESIVES

Knowledge of the special adhesives, and the respective surface for which they are recommended, is critical in obtaining superior installation when using Thin Slate Stone veneer. We recommend testing the selected adhesive prior to proceeding with installation. Humidity and temperature of the environment is to be evaluated first. If the application is outdoors, consideration to thermal expansion should be taken into account. Thin slate Stone is a veneer, it must expand and contract which is recommended by the adhesive manufacturer, the bond must be tested by the installer prior to final installation.

Knowledge of the special adhesives, and the respective surface for which they are recommended, is critical in obtaining superior installation when using Thin Slate Stone veneer. We recommend testing the selected adhesive prior to proceeding with installation. Humidity and temperature of the environment is to be evaluated first. If the application is outdoors, consideration to thermal expansion should be taken into account. Thin slate Stone is a veneer, it must expand and contract which is recommended by the adhesive manufacturer, the bond must be tested by the installer prior to final installation.

Recommended types of adhesives & fillers:

- Polyester-based gap filler putties

- Epoxies

- Silicone (with primer only)

- Polyurethane wood glues

- Thick latex-type adhesive, thin set etc. (uses only where air-drying can take place)

- Construction grade multi-purpose adhesives (eg. Liquid Nails or PL Premium Polyurethane or similar)

Note: The back of Thin Slate Stone Veneer may require a filler-type adhesive in some cases. Polyurethane wood glues work well for most applications to fill gaps. For wet environment such as shower and bathroom applications, the use of epoxy is best. Note: Pressure sensitive adhesives are also recommended due to the even backing of the Thin Slate Stone Veneer. Now Pressure sensitive glues are applied on the back of Thin Slate Stone Veneer and is supplied with the paper cover to use it as peel and stick material ready to use

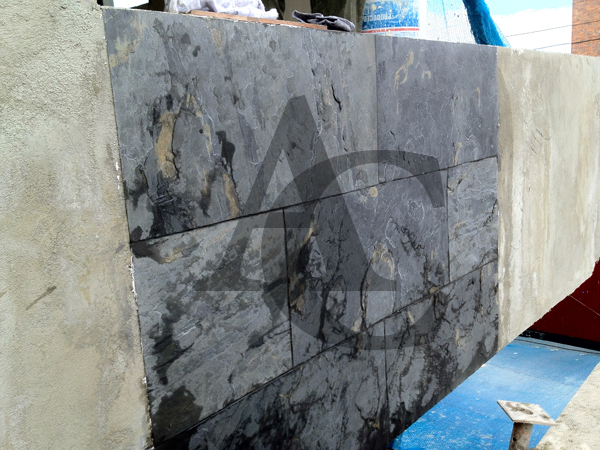

TILING

Thin Slate Stone Veneer can be used to create a tiled effect by leaving a grout joint between cut pieces of material. Test results have shown the use of water-based epoxy grouts work well to fill between the cut veneers. By removing the material just under the grout joint, a deeper grout can be achieved if desired. Epoxy grouts are available in many colors to match or co-ordinate with the different colors of Thin Slate Stone. On final clean up of the epoxy with a sponge, the epoxy can also be used to seal and fill the Thin Slate Stone surface. It is recommended in this installation that the entire surface of the Thin Slate Stone be sealed with epoxy as a final step to ensure complete satisfaction.

Thin Slate Stone Veneer can be used to create a tiled effect by leaving a grout joint between cut pieces of material. Test results have shown the use of water-based epoxy grouts work well to fill between the cut veneers. By removing the material just under the grout joint, a deeper grout can be achieved if desired. Epoxy grouts are available in many colors to match or co-ordinate with the different colors of Thin Slate Stone. On final clean up of the epoxy with a sponge, the epoxy can also be used to seal and fill the Thin Slate Stone surface. It is recommended in this installation that the entire surface of the Thin Slate Stone be sealed with epoxy as a final step to ensure complete satisfaction.

SEALERS

Thin Slate Stone Veneer can be sealed in the similar manner as most slate and / or stone tiles are sealed. Please follow manufacturer's instructions for best results. As sealants are offered in varying degrees of luster or sheen, we recommended that you confirm the reflectance prior to complete installation to get the desired effect.

Thin Slate Stone Veneer can be sealed in the similar manner as most slate and / or stone tiles are sealed. Please follow manufacturer's instructions for best results. As sealants are offered in varying degrees of luster or sheen, we recommended that you confirm the reflectance prior to complete installation to get the desired effect.

STRUCTURE & BACKING

Thin Slate Stone is a Natural Stone Veneer lamination with smooth black backing. It is produced with a fleece backing in black color having a seam in the middle which appear when the light is passed through it

COLOR VARIATIONS

Thin Slate Stone Veneer is a Natural Stone Veneer, color & texture variations are the property of the material. Texture variations with color difference are a inherent part of the natural beauty of quarried material. Stone Veneer can not be guaranteed to match with each Lot, it is recommended that material should be accepted in lots of 20,40,50 sheets to match. Large orders will be executed in bundles of 50 with 2-3 matching lots in each bundle. Exceptions of large lots are also a possibility.

Thin Slate Stone Veneer is a Natural Stone Veneer, color & texture variations are the property of the material. Texture variations with color difference are a inherent part of the natural beauty of quarried material. Stone Veneer can not be guaranteed to match with each Lot, it is recommended that material should be accepted in lots of 20,40,50 sheets to match. Large orders will be executed in bundles of 50 with 2-3 matching lots in each bundle. Exceptions of large lots are also a possibility.

USES FOR LAMINATION & DIRECT GLUING

Thin Slate Stone is used for wall panel on MDF, HDF board's application, furniture, woodworking machines, round column cladding and numerous interior and exterior applications. Thin slate stone veneer is also recommended for flooring or countertop applications after sealing the surface of the stone veneer with epoxy sealers to avoid scratches & abrasion. Polyurethane sealers can also be used if stone veneer is used for domestic applications. Stone Veneer can directly be glued to concrete floors and walls with the help of epoxy and other PU glues Thin Slate Stone Veneer may be used in illumination application such as lamp shades or back light applications as translucent material or the other translucency applications.

LIGHT, HEAT & TEMPERATURE RESISTANCE

Stone Veneer has natural stone surface layer surface which acts as a UV light or UV rays protector and will resist high sun conditions for years. When it is glued to a substrate, Slate Stone veneer will handle high thermal contraction and or expansions of most standard construction materials. Thin Slate Stone Veneer will handle both high temperatures and freezing without cracking.

SUBSTRATES

Thin Slate Stone can be applied to MDF, HDF boards, Styro Foam sheets, melamine, concrete, brick, concrete blocks & slabs, mortar plastered walls, drywall, plywood, acrylic and other plastic sheets.

TOOLS FOR CUTTING

Diamond blades used for marble & stone cutting can be used for cutting Thin Slate Stone Veneer. Metal cutting tools also can be used to cut the Stone Veneer. Any standard carbide or diamond saw blades would work just as well.

CURVATURE & BENDING

Thin Slate Stone Veneer can be bent with same flexibility as any plastic sheet product. The backing used gives it enough strength and flexibility. Thin Slate Stone Veneer can be bent in concave & convex forms, or arched or radial forms depending on the nature of curve. Thin Slate Stone Veneer can be bent or flexed to a radius of 380mm along the 1200mm length. The 600mm width will also have a slight flex to it, but is not recommended for bending. Due to the nature of the different thickness of the individual items, the degree of radius varies per item. We recommend testing the flex of the considered item prior to final installation.

Sealers & Glues for product application

1. POLYESTER RESIN SHEETS (NORMAL GRADE):

Stone Veneer sheet are mainly constituted of fiberglass & polyester resin. There are three kinds of resin. Namely, normal sheet grade resin, fire retardant resin and Ultra Violet resin. The classic grade sheet material is made from normal polyester sheet grade resin.

2. FR RESIN SHEETS (FR GRADE):

FR Resin sheet is made from fire retardant polyester resin. Main constituent of the sheet is resin which in this case is based on Isophthalic resin, manufactured by physical addition of halogenated additives and antimony trioxide to give excellent fire retardant properties with reference to IS 6746. This resin has the added advantage of chemical resistance to several acids and solvents etc. It is recommended for use where fire hazards are one of the main considerations besides the requirement of chemical corrosion resistance.

3. POLYESTER RESIN SHEETS (TRANSLUCENT UV GRADE):

Stone Veneer sheet are mainly constituted of fiberglass & polyester resin. Sheets made from Ultra Violet resin are Translucent and is made from Ultra Violet resin.

4. MONO STONE VENEER:

This material is made with cotton fabric & Ethylene Vinyl acetate copolymer Glue which is white emulsion and is water based. The final product is called Mono Stone Veneer because it is 100% eco friendly and without any solvent based glue. This is environment friendly and is very flexible as compared to normal polyester resin material.

5. STONE VENEER ON MDF & HDF:

Heat Press is required to press stone veneer on MDF/HDF under 10 Tons pressure and 120 degree centigrade heat to activate the glue for 2-5 minutes for good industrial results. Glues recommended are PU hot melt glue, white water based Polymer Emulsion called Ethylene Vinyl acetate copolymer Glue. The glue can be found in the local market.

Recommended websites for Glues & Sealers:

- www.laticrete.com

- www.wacker.com

- www.miraclesealants.com

- www.henkel.com

- www.akemi.com

- www.lantania.it

- www.kleiberit.com

- www.mapei.com

6. STONE VENEER ON CONCRETE OR MORTAR CEMENT PLASTERED WALL OR GYPSUM BOARD, EXTERIOR OR INTERIOR:

Epoxy based grouts available in the market with flexibility component are recommended. Contact local dealer / engineer of the area visiting website www.mapei.com www.laticrete.com or local suppliers of the similar products.

7. THE SELF ADHESIVE STONE VENEER

It is coated with pressure sensitive glues made in India. The pressure sensitive glue paper is available from Germany and can be made available on request.

8. SEALER & IMPREGNATORS:

All the stone veneer needs sealer & impregnators for stain & scratch protection. The sealers & impregnators available in the market are polyurethane matt & glossy, water based sealers & impregnators, solvent based sealers & impregnators & silicone based sealers & impregnators. All these sealers are similar to the ones used in sandstone & slate industries. Please visit www.miraclesealants.com , www.laticrete.com, www.wacker.com, www.akemi.com for your local dealer.

9 FLOORING:

Stone Veneer with more quartz contents is suitable for flooring on MDF & HDF and is being produced at present in Europe and Asia. If samples are required, can be forwarded on buyer’s courier number.

10. EXTERIOR APPLICATION SEALER COMPANY

http://www.lantania.it : TWINSTW (Name of Sealer)

Maintenance

Cleaning

(During installing with adhesives and joint material) When laying and grouting Stone Veneer should not have any rests of glue or adhesive on the surface. If this still happens, clean with basic tile cement cleaner (heavily diluted, short exposure, pre-test). If oil or grease contamination is on the surface use Intensive Cleaner. A follow-up of the slate tile can only take place after complete dehydration. Slate stone has the specific drying process during the deformation. That makes it essential to protect the area to be sealed because dirt, quartz sand, and/or concrete ruins the surface of the stone which is often quite soft.

Sealing of surface

By a single treatment with liquid sealer, almost all natural stone surfaces are easier to maintain. Not only water but also oil and grease can no longer penetrate into the surface. Sun spots are largely prevented and they are easier to remove. For light loads in the interior, we recommend sealing for walls, ceilings, furniture and kitchen fronts. This is good for all surfaces without too much use.

To keep beauty forever

All natural stone surfaces, even if it is sealed, must be wiped regularly moist. As such we recommend using a shot floor cleaner in water (available in any hardware store) to clean and maintain in one operation. The material will not get exhausted, but with regular use keep more beautiful and rich in color. To maintain the gloss you should occasionally wipe with a gloss cleaner. For heavy wear surfaces you may need a special cleaner from time to time (available in any hardware store). This gives the surface an added protection and shine. In no case may leaching Lubricating soaps, abrasives, or strong acidic cleaners degreasing agents be used.

Important:

cleaners attack the polish and matte showed bodies - strong degreasing products are leaching or permanent maintenance care inappropriate.

Remediation of old surfaces

Oily, oily contaminants and residues of floor care equipment can be easily removed with basic cleaning or intensive care products. Refreshing of faded surfaces is easy done with oils.